Moldex3D MuCell® supports solid mesh projects only. The procedures in the pre-processing stage are similar to those for basic modules. Follow the steps listed below to set up your first core-back simulation.

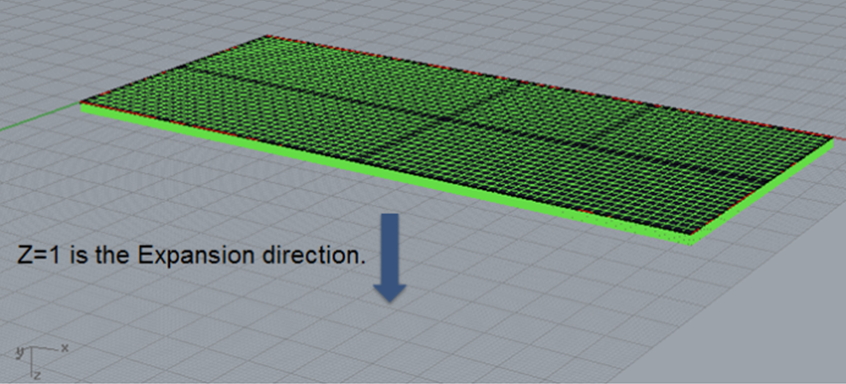

To run a core-back analysis, users can construct their geometry model with Moldex3D Mesh. The definition of the Moving Surface needs to be specified after the model mesh is built. In this example, we defined the direction of the moving surface as z=1.

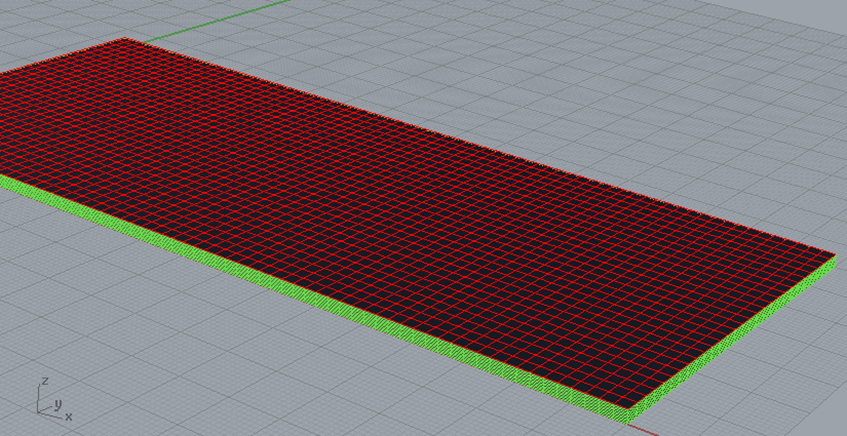

Select the moving surface as indicated by the red colored mesh, and click the down-right corner of BCsicon ![]() Â . When icon

. When icon ![]()  pops out, choose

pops out, choose ![]()  .

.

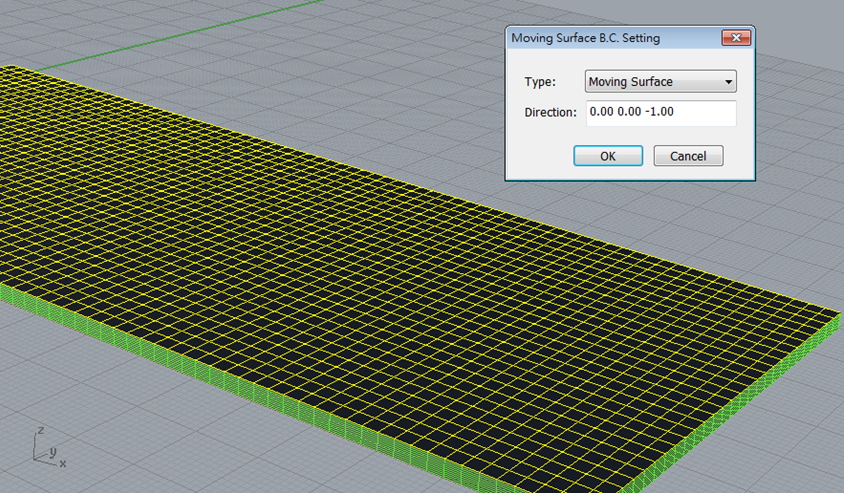

When the Moving Surface B. C. Setting dialogue pops out, users should define the direction as “0.00 0.00 -1.00â€. This setting means the moving side of the mold (moving surface) will be pre-closed in the z=-1 direction, then expanded in z=1 direction.

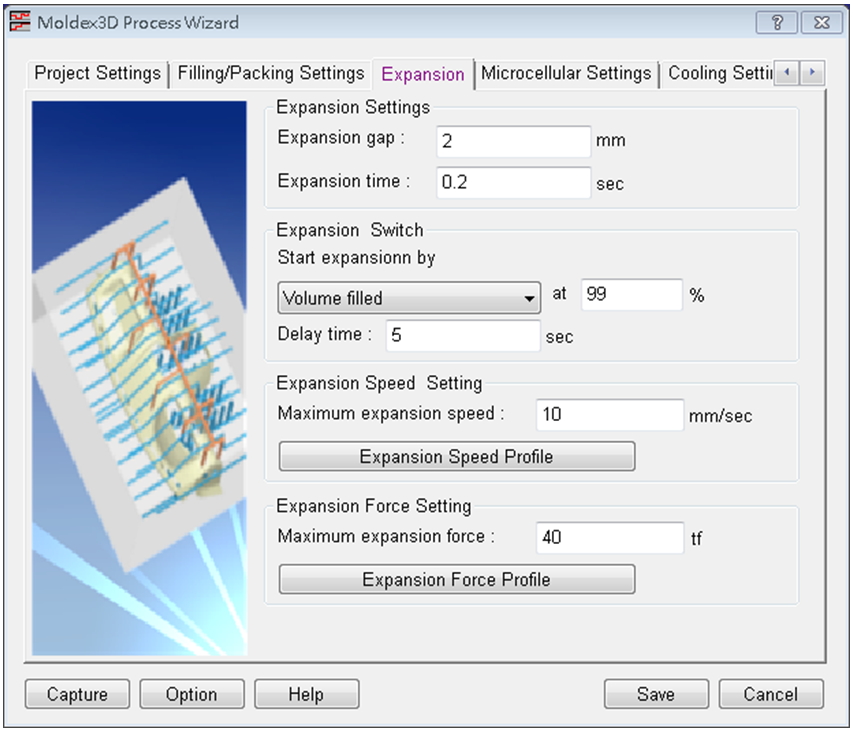

Expansion Settings parameters are Expansion gap and Expansion time, which are calculated according to the molding process.

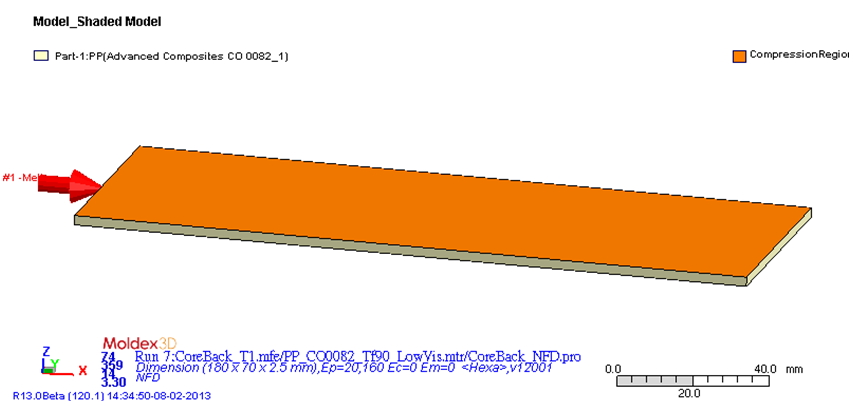

Once the imported mesh file (*.mfe) includes the definition of the moving surface, the Compression Region, as shown in orange, and will appear in the project.

Round Vibration Sieving Machine

Erbang company proffesional to design and manufacture the Vibration Sieving Machine/vibrating screen that include ZS Round Vibration Sieve and Vibrating Sieve , welcome to contact us and we will offer competitive price !

Vibration Sieving Machine main to separate the different size materials and get uniform materials. it main to install the step that after drying machine or Pulverizer Machine. when customer want to get uniform size materials , we will recommend the different machine to reach customer requirement, the Vibration Sieving Machine be made all stainless steel and the machine constraction also meet the requirements of GMP.

Round Vibration Sieving Machine,Round Sieve Machine,Vibration Screen Machine,Vibration Separator Machine

Changzhou ErBang Drying Equipment Co., Ltd. , https://www.hywellmachinery.com